RS-PACK

HOW IT WORKS

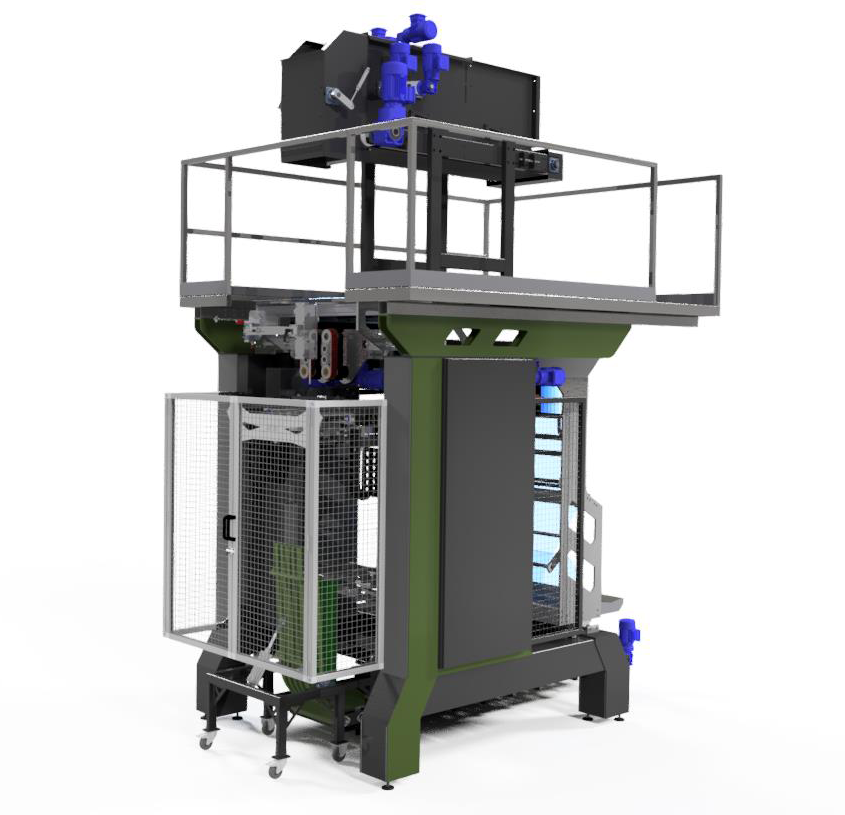

RS-Pack vertical bag packing machine

The packaging machine makes a bag hose from flat film by longitudinal welding, fills it and welds the lower and upper ends of the bag. Throw the bags onto the conveyor belt without damaging them.

The packaging machine operates continuously, so the welding head picks up the speed of the film during continuous film stripping. Foil vertical welding and longitudinally moving foil are cross welded and filled with raw material at the same time. After filling, the bags are supported from below and can be shaken by the support unit. The filling is intermittent and synchronized with the welding. The welding head is an integrated type that simultaneously welds, cuts and cools the seam of the bag. The transfer of the foil is an automatic process, monitored by sensors and continuously controlled by the intervention units.

Raw material:

bulk soil, flower soil mixture, pellet, any bulk material, etc.

Packing capacity:

5 liters 34 pcs/min

10 liters 32 pcs/min

20 liters 28 pcs/min

40 liters 24 pcs/min

70 liters 17 pcs/min

120 liters 10 pcs/min

Bag basic data:

Bag width: max. 700 mm

Bag length: max 1300 mm

Bag shape: PE bag side-folded or hose shape

Bag thickness: 50-140 microns

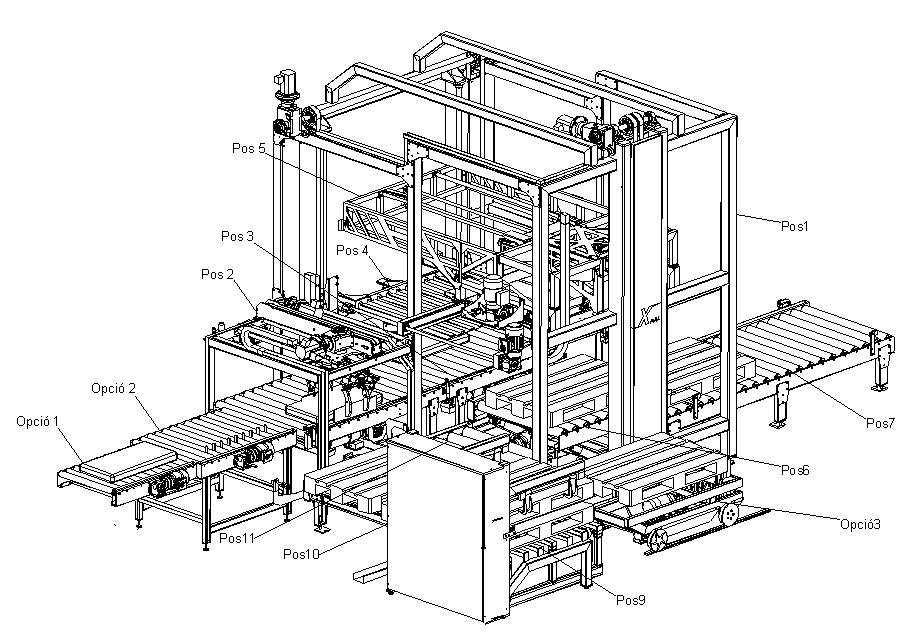

Type: X-pal 2000 palletizer

Technical specification:

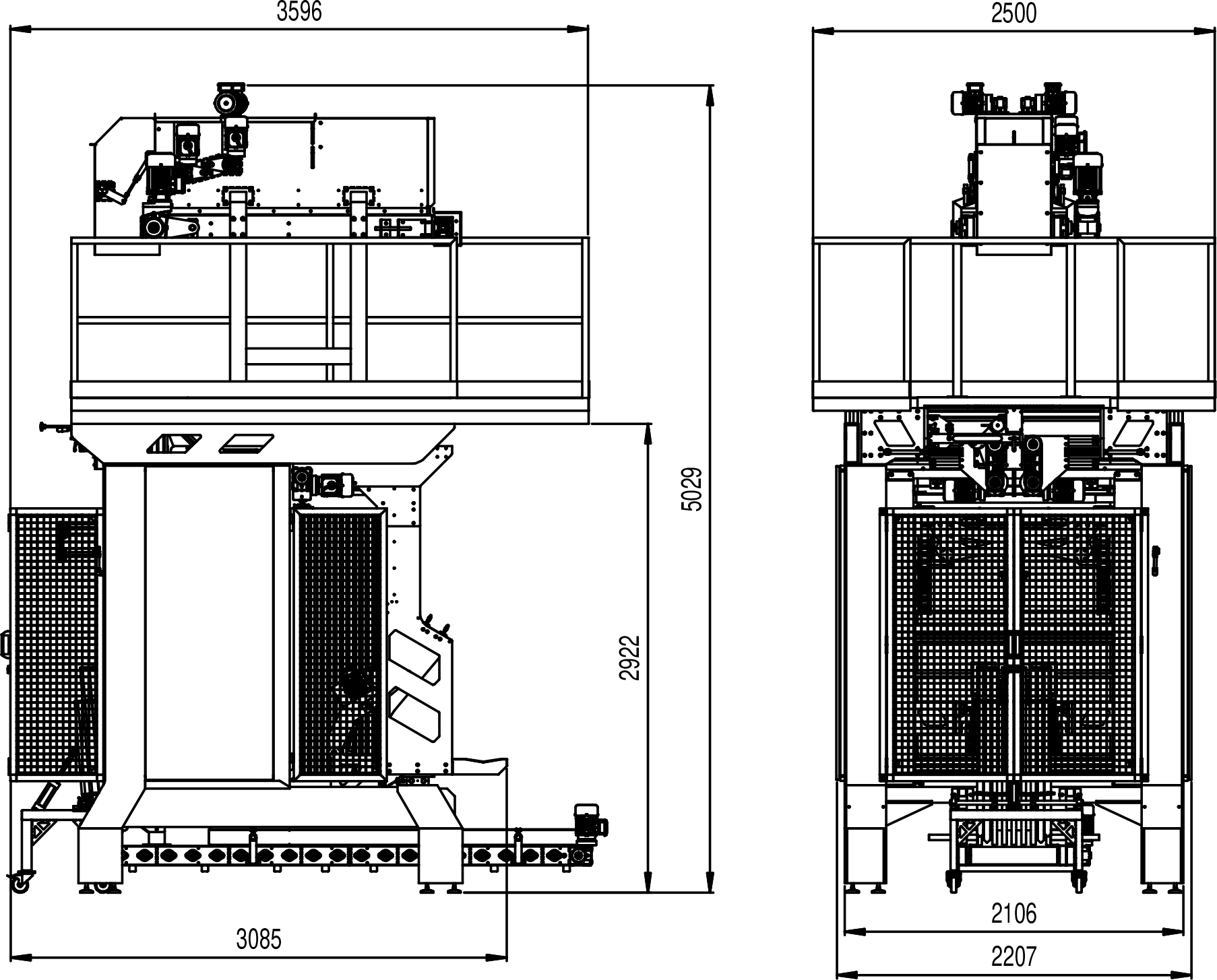

Net weight: approx. 5,900 kg

Color: RAL7011 and RAL7039

Length: 6700 mm

Width: 5415 mm

Height: 3380 mm

Electrical connection: 25 Amp main cable 50 Hz, 3×400 V Air demand: 6 bar, 150 liters / min

Control: Omron PLC

Gears: Nord

Performance data:

Product: PE bag filled

Bag sizes: 5-80 liters, 300x160x30 mm – 800x400x150 mm

Palletizing speed: Max 2000 bags / hour

Pallet height: 2000 mm

Pallet weight: 2 t

Pallet size 800×1200 Euro type

Other technical description of palletizer:

- The machine automatically loads empty pallets from the filling station and feeds them into the palletizer

- The finished pallets are automatically transferred to the stretch wrapper

- 60 pre-programmed layer training

- Automatic changeover in case of product change, no manual adjustment required

- Pallet vertical pressure

- Low friction surfaces for layer formation

- Roller tracks 500 mm above the ground. (adjustable option)

- EEC standard protection

- Multiple side pressure option

- Error display in case of operating error

- Touch screen industrial display

- Use of energy recovery system for bag lifting

- Energy efficient layer training and bag rotation

- Speed at 50liter bags – maximal 20 pcs/bag

Optional components:

- Scrap pick-up and drop-off

- Bag weight measurement

- Unit stack training from small bags

- Empty pallet carrier

Advantages of the machine:

- Every movement is designed for energy efficiency.

- The energy consumption of the machine is less than 3 kWh.

- It can be installed in a smaller space than a robot cell and also has a larger capacity

- There is no need to transport the bags high (which is very space consuming), palletizing is done at ground level.

- Optimized for the high-performance RS-Pack packaging machine.